How Catalytic Water Technology Works

CAPE HydroTek’s catalytic technology installs right into your existing infrastructure without any costly or disruptive overhaul, transforming your water system by minimizing chemical dependency, preventing scaling, corrosion, and biofilm formation, extending system lifespan, and maximizing uptime.

What is Catalytic Water Technology?

Unlike traditional chemical-based approaches, catalytic water management prevents scaling, corrosion, and biofouling at the molecular level. Our proprietary catalyst uses technology (instead of chemicals) to alter water's properties and keep your system clean, improve heat transfer, reduce downtime, and extend equipment life.

Integrates Easily into Your Existing Infrastructure

CAPE HydroTek’s catalytic technology is designed for easy integration into existing, traditional systems with minimal maintenance. The mineral metal catalyst is installed directly into the water system where it is most advantageous. For cooling systems, this is typically at the make-up water supply but may be at other points along the circuit. In all cases, installations are done with minimal modifications or downtime.

- No major equipment changes required: The catalyst works seamlessly within existing infrastructure.

- Minimal downtime for installation: Unlike complex water treatment retrofits, this technology can be implemented quickly.

- Long-lasting & minimal maintenance: Once installed the catalyst does not degrade, greatly extending maintenance intervals and reducing chemical adjustments.

Why It Matters: Smarter Water Management That Works

Traditional water management is costly and inefficient.Constant chemical dosing leads to high costs, unpredictable expenses, and compliance headaches. CAPE HydroTek’s catalytic technology cuts chemical use by at least 50%— reducing spend while maintaining compliance. |

Scaling, corrosion, and downtime disrupt operations.Equipment failures shorten system lifespan and cause costly unplanned shutdowns. Unlike chemical treatments that react to problems, our technology is proactive to keep systems cleaner and running longer. |

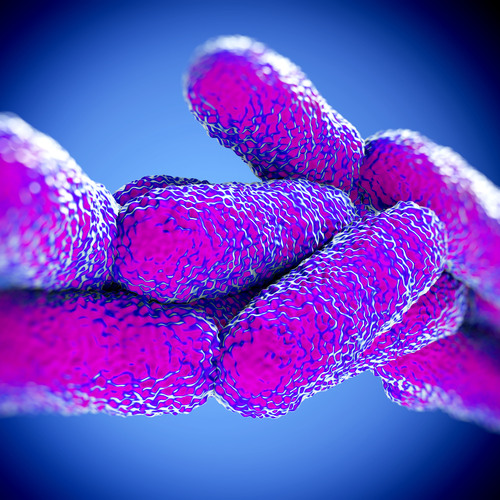

Pathogenic bacteria such as Legionella and biofouling create compliance risks.Regulations are tightening, and Legionella outbreaks lead to fines, shutdowns, and liability concerns. Our solution disrupts biofilm growth without harsh biocides, to easily maintain safer, compliant systems. |

What Makes CAPE HydroTek Different?

Traditional Chemical Treatment |

CAPE HydroTek Catalytic Technology |

|

X Constant chemical dosing required |

✔ Reduces chemical use by at least 50% |

|

X Scaling, corrosion, & biofouling still occurs |

✔ Prevents buildup before it starts |

|

X Risk of Legionella outbreaks & compliance issues |

✔ Disrupts biofilm formation for safer operation |

|

X Regular maintenance & system downtime |

✔ Minimizes downtime & extends equipment life |

Real Results with Smarter Water Management

✔ At least 50% reduction in chemical costs

✔ 100% biocide-free operation in power plants

✔ Reduced costs in energy, maintenance, and water usage

✔ Fewer shutdowns and extended equipment lifespan

Is Catalytic Tech Right for You?

CAPE HydroTek’s catalytic technology is designed for industrial plants and facilities that want to:

✔ Reduce water treatment chemical use by at least 50% without sacrificing performance.

✔ Eliminate scaling, corrosion, and biofouling that cause unexpected shutdowns and maintenance.

✔ Ensure compliance with Legionella and water treatment regulations without over-relying on harsh biocides.

✔ Easily integrate new technology with existing water systems (no major equipment changes required).

✔ Improve efficiency and equipment lifespan while reducing operational costs.

✔ Prevent unplanned downtime and extend your maintenance intervals.

Prevent Legionella

Legionella outbreaks can lead to costly fines, shutdowns, and compliance risks. Learn how our catalytic technology disrupts Legionella growth at the source—minimizing risk while reducing chemical dependency.

Keep Water Clean & Safe

Traditional water treatment depends on constant chemical dosing, rising costs, and reactive fixes. Discover how catalytic water management delivers stable water quality, minimizes waste, and optimizes system performance.

Explore Industry Applications

From power plants to food production to manufacturing, CAPE HydroTek helps industrial facilities reduce chemical use, improve uptime, and ensure regulatory compliance. See how we serve your industry.

What Happens Next?

Step 1: Book a quick call with our experts.

Step 2: We'll analyze your facility’s water system to identify cost-saving opportunities.

Step 3: You'll get a customized report on how you could save and improve efficiency.

Get Your Custom Water System Assessment

Contact us to see if catalytic water management can reduce your chemical spend, increase uptime, and extend equipment life.